Propylene is one of the popular polymer materials in the plastic industry. This white material is widely used in the production of plastic products and fibers. Due to its thermoplastic properties (easy deformation with heat) and good stability of propylene at ambient temperature, this material is widely used in many plastic products and everyday fibers, and it has caused propylene to be considered as the most widely used plastic material in the world. to be In today’s world, a large part of the artifacts that we use every day are produced using propylene materials.

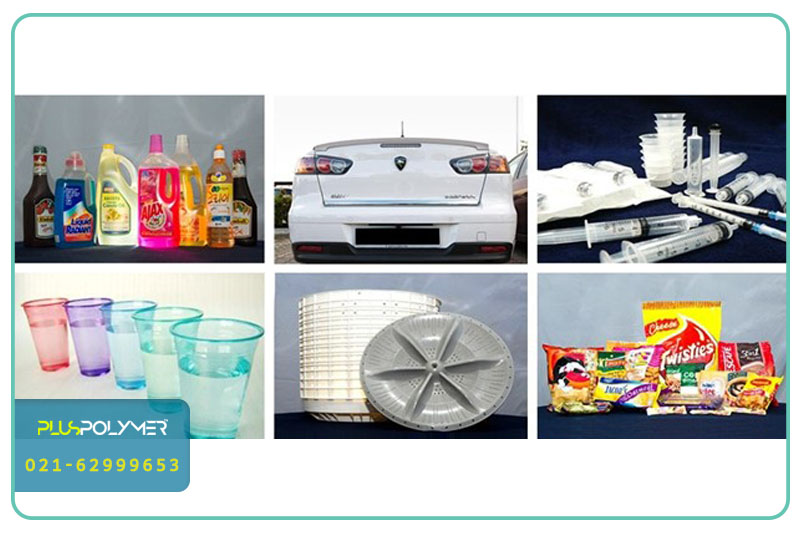

Polypropylene (PP) is a thermoplastic that is made from the combination of propylene monomers by the addition polymerization method (chains). Polypropylene is used in various applications, including packaging of consumer products, plastic parts for various industries, including the automotive industry, to textiles, clothing, and medical supplies.

In this text, we are trying to take a closer look at propylene and see what this polymer is. What types are there? And its price is determined based on what factors? So, join us to get acquainted with the beautiful and attractive world of this widely used and practical polymer.

Propylene, sometimes abbreviated as PP (read PP), is a monomeric polymer that has thermoplastic properties. This polymer is actually a highly branched hydrocarbon resin and has carbon (C), hydrogen (H) and methyl groups (CH3) compounds in its chain. The written formula of propylene is written as -[CH2-CH(CH3)]n- or the molecular formula (C3H6)n and has the following structural composition:

In the propylene industry, it is known by different names such as Polypropene, Polypropylene, Polypropene 25 or Propylene Polymers.

Properties of propylene

Propylene has three spatial configurations in its structure, which can be referred to as isotactic (iPP), syndotactic (sPP) and atactic (aPP). iPP type is widely used in the industry. This monomer is resistant to water absorption. In addition, it can change the polymer properties of propylene by adding different catalysts.

Propylene has a standard density of 0.855 grams per cubic centimeter, and therefore it floats on water.

Propylene melts or becomes fluid at a temperature of about 130 to 171 degrees Celsius, depending on its type. However, it maintains its resistance at ambient temperature (between 20 and 40 degrees Celsius). This factor has caused many artifacts to be made with propylene in today’s world.

In addition to the chemical and physical properties mentioned above, propylene also has the following industrial and commercial properties:

Propylene is one of the cheapest polymers and therefore it is cost-effective to make artefacts with it;

Propylene is lightweight and its artifacts float easily on water;

Propylene has very good flexibility and this is an added advantage for it;

Propylene is resistant to water penetration, this factor makes it possible to use it to make food and sanitary containers;

Propylene can be combined with other polymers to give us multiple alloys. This issue plays an important role especially in the waste and plastic recycling industry;

Propylene can be used as a suitable substitute for other propylene such as PE or PS.

In the plastic industry market, we have various grades of propylene. Different grades can be created based on changes in the polymer chain, addition of catalyst, addition of other polymers, or propylene manufacturing and granulation methods. Also, raw materials can provide us with high-quality or high-quality propylene grades.

The most basic method of producing different types of propylene is to change the structure in its polymer composition (apart from its mechanical production method). In general, in polypropylenes, we have two structures:

Homopolymer structures: where the polymerization is done in one way (monomeric) and the final product is propylene. This product is hard and has high tensile strength. But it is fragile to impact. Here we are dealing with a product with good thermoplastic properties, but the high flexibility may limit us in making artifacts. Homopolymeric structures are very suitable for the production of fibers.

Copolymer structures: where polymerization is done with ethylene comonomer, as a result of which we will have a multi-directional structure (copolymer) that can acquire special properties depending on its development. This product has a relatively weaker structure and shows less tensile strength, but it has higher impact resistance. Of course, the weaknesses here may be compensated by the addition of catalysts and other structures. At the same time, the thermal and physical properties will change depending on the added carbon structures.

Polypropylene also has a lower density (gr/cm-30.85-0.93) than other common plastics such as polystyrene, high density polyethylene, nylon, polycarbonate, polyurethane, polyethylene terephthalate and polyvinyl chloride.

At room temperature, it has high chemical resistance against organic solvents such as fats, but at high temperatures, it is subject to oxidation.

Polypropylene was first polymerized in 1951 by two Phillips petroleum researchers, Paul Hogan and Robert Banks, and then by Italian and German scientists Nata and Wren. This material became widespread very quickly, and commercial production of polypropylene began approximately three years after the first samples were produced by the Italian chemist Professor Giulio Natta.

Nata synthesized the first sample of polypropylene in 1954 in Spain, and at the same time the crystallization ability of polypropylene attracted much attention. In 1957, its popularity increased and large-scale commercial production began throughout Europe. Today, polypropylene is one of the most commonly used plastics in the world. This polymer is made from the addition polymerization of propene monomer. The two main methods for producing polypropylene are:

Polypropylene as an olefinic thermoplastic shows unique characteristics that make it suitable for a wide range of applications. For this reason, after the synthesis of the first samples of polypropylene, its production and consumption spread all over the world in a short time. The mechanical and chemical properties of polypropylene, along with its availability and affordable price, have made many products, including electrical insulation, car parts, home appliances, and industrial tools, to be made from this material. Despite the excellent features of polypropylene, it is necessary to overcome the weaknesses of this polymer such as copolymerization and blending. The use of new additives, polymerization processes and compatibilizers significantly improves the performance of polypropylene. Therefore, today polypropylene is seen less as a low-cost solution, but more as a material with high efficiency and improvement capability.

Types of polypropylene grades and their structural form can be found in the market of polypropylene grades as follows:

In general, propylene homopolymers have three categories:

Ataktisch (Ataktisch) which are known as irregular structures. These materials are melted at a low temperature and become fluid, and due to their molecular structure, they can be used to make adhesives. Atactics are transparent, flexible, and at the same time have a coherent and rigid structure.

Isotactic (Isotaktisch), which are known as the structures of an order (strata) or even order. Isotactics melt at high temperature and have a crystalline structure.

Syndiotactic (Syndiotaktisch), which are known as single-order structures. Syndiotactics have less clarity, but are generally transparent. They are a bit difficult to work with and depending on their grade, they can be melted and shaped at different temperatures.

Copolymers can exhibit different properties depending on the type of additions to the molecular structure of propylene polymer. Here we are faced with larger chains that can offer us different strength, flexibility and fragility.

In general, we are faced with the following two general categories in copolymers:

Random copolymers (Random): These copolymers are often transparent and can easily be used to produce common household artifacts. Tubular extrusion and pressure can be used to form this group of copolymers. This propylene has good resistance to sunlight and its temperature is close to propylene.

An example of a random copolymer

Impact copolymers: These copolymers cannot be molded easily. To mold them, methods such as blowing injection or thermal films should be used. But the products made with copolymers have high impact resistance. For this reason, copolymers are used to make products that are used in the automotive industry.

Examples of impact copolymers

In the table below, you can compare the properties of both groups:

The process of producing products from propylene

Depending on whether propylene is homopolymer or copolymer, different methods are used to shape it.

If our propylene is homopolymer type, tubular extrusion method and heavy press molds are used to shape it. In this case, the propylene is heated and softened after passing through a tube and a rotating screw or pressure cylinder, then it is inserted into a metal mold and takes the shape of the mold. The cooling process is done quickly in the mold by circulating water or blowing cool air. In the production of this category of propylene, it is possible to use grain color, catalysts and plastic supplements.

If we use copolymers, we must pay attention to the type of copolymer. In most cases, propylenes of this shape are produced in the form of films of the desired thickness and heated, and then stretched on the mold by evacuating the air below it. This is exactly like putting cellophane on things. This method is a common solution in making refrigerators, car bumpers or other large artifacts. In some materials that copolymer allows us to inject, methods such as tubular extrusion or pressure are used to inject it into metal molds.

The major final consumers of polypropylene are in the packaging industry, which accounts for about 30% of consumption, followed by the production of electrical equipment and tools, which each consume about 13%. Household appliances and automobile industries also consume 10% each, and finally, construction industry-related uses are in the next rank with a 5% share of the market.

One of the important features of polypropylene is its low friction coefficient, and it has a relatively polished and slippery surface, making it a suitable substitute for materials such as polyester for use in areas where low friction coefficient is required. Production of gears or points in the vicinity of furniture contact are such cases. Of course, the negative side of this feature should also be considered. This relatively smooth and frictionless surface makes the normal adhesives, which have good performance and strength against other polymers, perform poorly for gluing polypropylene parts to the extent that in some cases melting and welding are required to connect polypropylene parts. It is giving parts.

The world of propylene is very numerous and diverse. The type of propylene and production and supply processes can have a direct impact on the price of propylene. In general, homopolymer type propylenes are cheaper. But this is not a general rule because determining the price of propylene is a multi-factor process and only the cost of production does not affect the price of propylene.

The price of propylene can be determined based on the following:

Being a homopolymer or copolymer;

production process in the refinery;

Shipping, warehousing and customs process;

daily exchange rate;

demand level;

Interest requested by intermediaries;

However, propylene is a widely used product in today’s plastic world, and many companies use it to produce their own products.